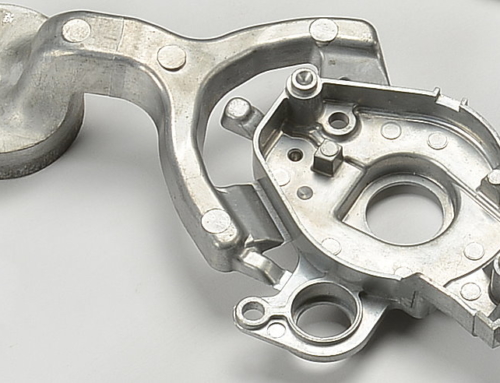

If you have ever been to an industrial set up, you would have definitely noticed those big machines. Ever wondered how the parts used to create these machines are manufactured? Well, they are manufactured using the process of die casting.

In layman terms, die casting is the process of creating complex metal parts using reusable molds. These molds are termed as dies, and hence the name – die casting.

When it comes to die casting, there are generally two types of machines used in the process –

-

Hot chamber machines

As it is evident from the name, these machines use high temperature to create the casts. These are generally used when dealing with allows for metals having low melting point, the most prominent example being Zinc.

-

Cold chamber machines

The second type of machines used for manufacturing dies involves low temperature treatment. These are used for alloys of metals that have high melting points. Examples of such alloys include aluminium metal, to name the major one.

The entire process is a highly intricate one and requires strict adherence to quality standards. After all the die casting process is going to yield products that will be used in high-end machines used for industrial purposes. Hence, you cannot afford to compromise on the quality of those machines.

Thanks to professionals like EverSkill Industries, getting world class die casting supplies has become quite easy for industries. Having years of experience in the business, these professionals have managed to help industries grow by supplying them with world-class machine parts.

If you are looking to get some quality parts manufactured, without having to invest a lot of time running everywhere in the market then getting in touch with these experts can prove to be the best idea.

Go ahead and check out their services to see what you can expect to get!