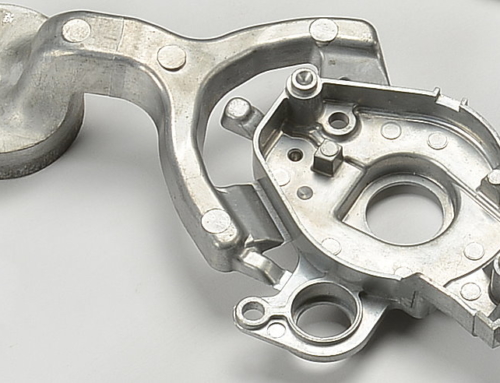

For those of you who don’t know, CNC machining is the process of using Computer Numerical to Control to operate machine tools such as routers, grinders, mills and lathes. In layman terms, it is like using a computer to operate a machine rather than having any human intervention in it.

Over the recent past, this process has been quite popular for industrial manufacturing process such as die casting. If you are wondering what makes it a better option as compared to manual machining, then here is a look at the reasons –

-

Easily scalable processes

One of the biggest advantages of CNC machining, when compared to conventional processes is that it can be scaled up pretty easily. All you need is just a few programming changes, and the machine can execute higher quantities that it used to do before.

-

Efficient products

Considering the fact that CNC machining requires minimum human intervention, one can be certain about getting more efficiency in the processes. As these computer-based machines can run round the clock, orders can be processed in lesser time.

-

Increased profits

When products will be delivered in lesser time, business gains will automatically increase. After all, you will be able to get more done within the same duration. And, hence you can fetch more clients and earn more profits.

Apart from all these reasons, the biggest thing about CNC machining is that it increases the efficiency of processes. There is no need to monitor different equipment by different individuals. Everything can be done from a single place, using a single monitor.

And, that’s the ultimate reason why CNC machining has managed to grab the attention over the recent past. If you are also looking for someone who can help you with this, then going to EverSkill Industries can be the best idea!