Lean Manufacturing

Here at EverSkill, we don’t just talk about lean manufacturing. We put it into practice every day. With each task we undertake, we strive to minimize waste, maximize efficiencies, and reduce lead times. To make this ambitious goal a daily reality, all of our team members are trained in Lean Manufacturing techniques and the Kaizen philosophy of continuous improvement.

This company-wide approach drives each of us to seek new methods for combining operations, simplifying tasks, and minimizing material handling. And with our nimble, flexible approach to manufacturing, we can quickly implement quality improvements, scrap reduction techniques, and a wide variety of operational efficiencies, from small process tweaks to major equipment upgrades. So you always get the best possible product—in the shortest possible time frame. Lean Manufacturing throughout our factory

Explore some of the specific lean techniques we use for:

- Extrusion

- Fabrication

Anodizing

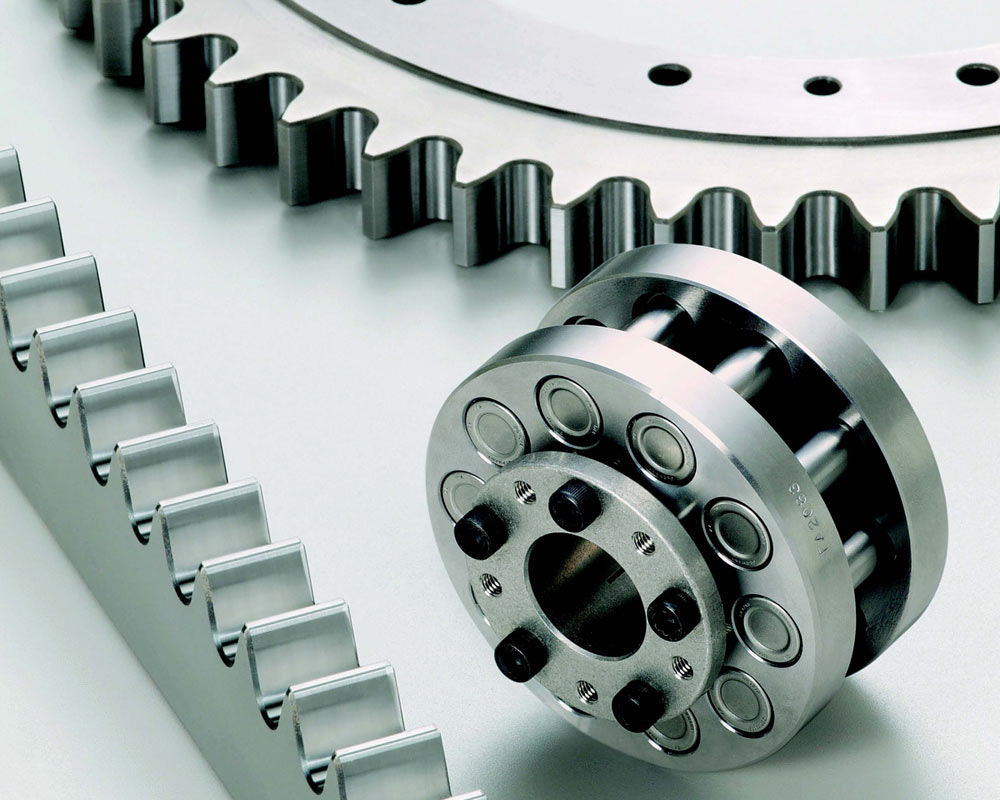

Machining

- Packaging